Moroccan Rugs. What You Need To Know.

The North African country of Morocco has become a very popular tourist destination, and the tribal minimalist and geometric designs of the region have become equally popular in homes.

The growing demand for this “look” has led to some inferior production centers to take shortcuts to bring goods faster, and cheaper, to market.

Though there are some very good quality, highly decorative textiles being woven in Morocco today, the bad ones are creating disasters that are tainting the reputation of the region’s weaving traditions.

Here are some of the areas where shortcuts are being made, how to spot the signs of bad production.

MOROCCAN FIBER SHORTCUTS

The sheep from the higher elevations in Morocco grow a stronger, higher quality wool than those in the lower elevations.

Because the lower quality wool is less cost to purchase, some operations looking to cut costs will source the lower quality wool and blend it with other natural and synthetic filler fibers to try to give it enough strength to weave a rug out of it.

A good quality longer pile shag Moroccan rug may shed in the first months of its life simply as the result of a release of loose staple fibers or short pieces left over from the shearing process.

The difference in the wool quality is that higher quality wool with higher quality yarn production will see the shedding stop relatively quickly. The poorer quality wool and production will shed for its entire lifetime because the fibers have no inherent strength to begin with.

If you have a Moroccan rug that is heavily shedding, you will want to also inspect the rug for moths. These “shortcut” rugs tend to not have a thorough cleaning process during production, and the chances of moth eggs and larvae coming into the home from these rugs is very high.

(For tips on how to inspect for moths, visit Moths Bugs and Rugs. What you need to know.)

MOROCCAN DYEING SHORTCUTS

Over the past few years a growing complaint has emerged from rugs in this region of strong offensive odors. From our rug shop experience, and based on readers of my Rug Chick blog sharing their Moroccan rug “awful odor” stories, these rugs tend to be rugs that are heavily faded on the front side compared to the back. They tend to be embroidery and soumac stitching styles.

The odors come from either after-market chemical bleaching of the rugs, and/or heavy chemical (and sometimes toxic) use in the dyeing process of the fibers being used.

With the extremely faded rugs, spraying down the face of these rugs with bleach solutions and setting them in the sun is the process of creating a softer, more distressed look. You can identify these rugs by simply looking at the back and seeing if the coloring does not match.

With these rugs in particular, a spill on the front (or an inattentive cleaning process) can wick up the colors from the back and unintentionally change the look of these rugs. Bleach is a toxic chemical to use at the strengths needed to create this type of fading, and this odor often lingers with the rugs for some time.

Other foul odors can pose a more serious problem than bleach does.

Dan Driscoll, founder of The Anou (a network of weaving and artisan co-operatives in Morocco) did field research into some noxious odor complaints and discovered that several major suppliers in the region are using chemicals, such as formaldehyde, to shortcut the dyeing process.

Not only is this creating health issues for local weavers (as well as consumers buying these rugs), but the quality of the dye strike to the fibers is so weak that even simple water spills can mean a dye bleed disaster to these rugs. Dan writes about this in his blog at: Click Here for Full Article.

These couple bad dyers produce some of the worst quality fibers in the region and are the source of some of the most problematic rugs coming out of Morocco. So when shopping for Moroccan rugs, be attentive to whether the rugs have any odors.

Rug cleaners recognize these problem rugs as the rugs their clients spill plain water on and a large ink stain emerges. Or a clean-up area where all of the color has been removed in the blotting process. These also are the rugs that can dramatically turn a rug wash floor into dye soup if you do not know that the dye process is flawed.

RUG CLEANERS: PROTECT YOUR TEAM AND YOUR CLIENTS

In the world of Moroccan rugs, when the rugs are bad, they are very bad. This means a standard fiber test and a standard dye test will alert you to a serious quality control problem. The basics will save you, so do not skip them.

A visual inspection of the front and back of the rug will also provide you the information that you need to know if the rug has been chemically washed.

Your nose will tell you if there is a more serious situation at hand. The worst of these rugs are the ones that cause allergic reactions in their owners. When you get a call that someone has a newly purchased Moroccan rug with a horrible odor, recommend that they move the rug out of their living space until they can decide whether or not they want to return the rug back as flawed product.

If you decide to wash the rug to attempt to remove the odor, which may take more than one wash, take the proper precautions in case the issue is indeed formaldehyde.

If you have designers and customers seeking out Moroccan rugs, or planning a trip to the region, give them tips on inspecting quality. Using their thumbnail to scratch the fibers to see if they easily break and pull apart (a sign of bad wool). Using a damp handkerchief to test dye quality. Using the “sniff test” to see if something seems odd with the rug.

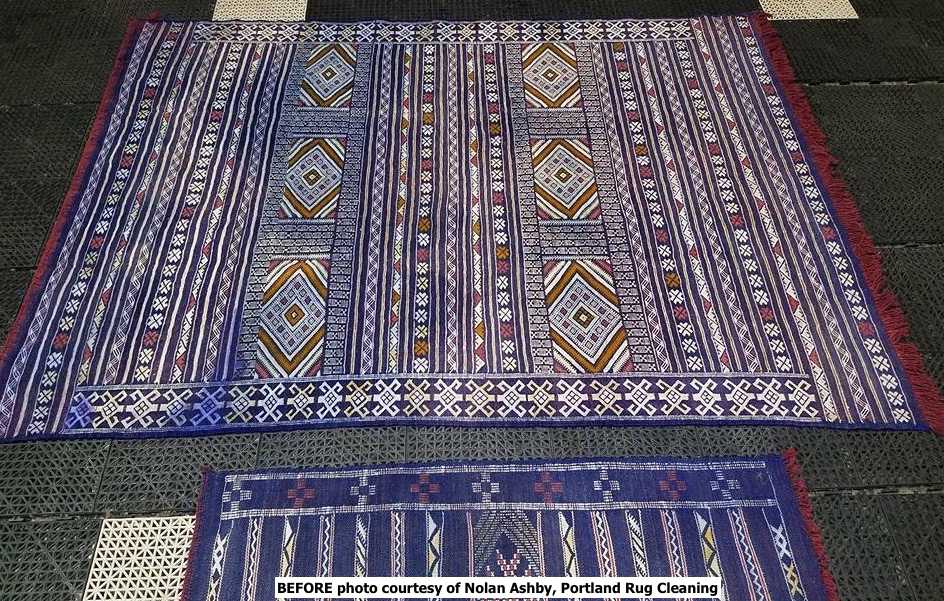

New Moroccan kilim rugs damaged in shipment by moisture which caused the lower quality dyes to bleed.

With awareness of these problem rugs in this region hopefully we can see these shortcut suppliers get pushed out of the market.

HAPPY RUGS

Moroccan rugs, the quality ones, wash up beautifully, and will last their owners a lifetime.

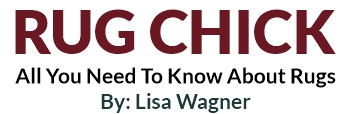

Quality Moroccan rugs have high sheen wool with rich, happy colors. They are rugs that always bring a smile to my face.

I hope these tips help you to avoid the poor choices.

If you need any feedback on a Moroccan rug you are looking at, you are welcome to reach out to me for care tips or input regarding fiber and dye quality.

Happy Rug Shopping!

Lisa

P.S. If you are looking for a place to buy some contemporary original weavings by Moroccan artisans through an organization that strongly supports women in the region to make their own living, I can’t say enough good things about The Anou (www.theanou.com). I have been a fan of theirs for years.